Intelligent Manufacturing

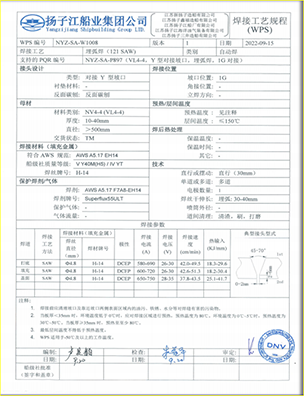

The company has a state-of-the-art physical and chemical lab equipped with over 20 sets of testing instruments including 1000KN tensile tester, -196°C low temperature impact tester, automatic turret hardness tester and advanced software systems (fast test+EMT impact). Currently there are 3 certified physicochemical testers capable of independently conducting various tests on materials. Through technological R&D, the company has over 150 certified welding procedures for materials including carbon steel, low temperature steel, low temperature high manganese steel, 9Ni steel, 5Ni steel, stainless steel and aluminum that have passed reviews by major classification societies like CCS, DNV, LR, NK, ABS. In non-destructive testing, the company has adopted advanced PAUT testing technology featuring no pollution, no radiation and high testing efficiency, leading the industry peers.

Application of Intelligent Manufacturing

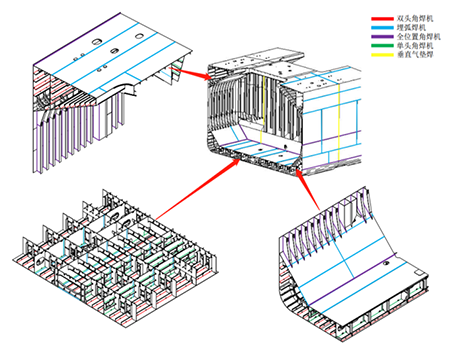

The company currently operates over 200 highly efficient equipment including CNC laser cutting machines, automatic T-bar production lines, gantry multi-head welding machines, fully automatic welding carriages, twin wire SAW, vertical gas metal arc welding, SAW side beam line, CNC lettering carriages, robotic sandblasting machines, etc. The percentage of highly efficient equipment reaches 55%. Through marking working areas and networking all highly efficient equipment based on production drawings, the coverage of highly efficient welding exceeds 80%.

The company attaches great importance to the application of intelligent manufacturing. Through continuous efforts on assembly lines, high quality, high efficiency and intelligence, strong momentum is injected into the company's high-quality development.

Application of Intelligent Manufacturing

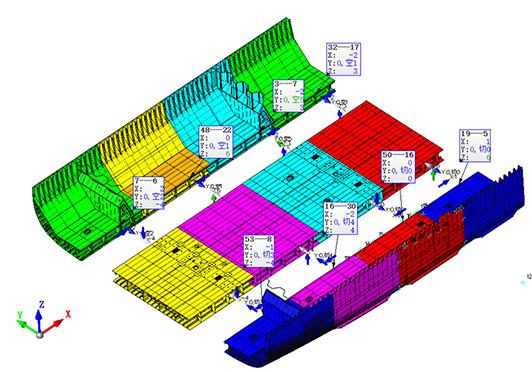

Learning from Japanese and Korean shipbuilding models, the company has introduced WL/BL baseline construction technology, total station measurement, precision simulation analysis and digital shipway erection technology that are also widely applied. The original arc retainment rate upon erection exceeds 98%.